|

|

Hooray!!! Our site has been updated. The site has become faster and clearer.Go to the new siteRelated products

JoomShopping Download & Support Latest news17 Apr. 2019

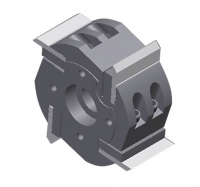

Modernization of the Multi Blade Pulpwood Machine UPT-250M

05 Dec. 2018

Universal tool-grinding ZS-1000 machine Universal sharpening machine for UPT-250M 05 Dec. 2018

Updates on the machine UPT-250M Now the UPT-250M machine will be equipped with manual tilters of the log, and the power of the cutter motors will also be increased. |

|